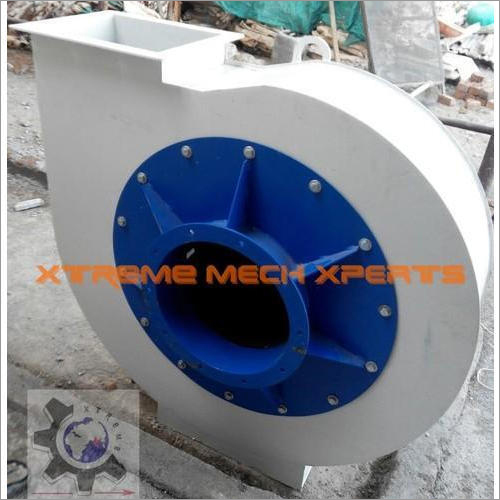

Centrifugal Blowers For Hot Air Generators

Price 28000-700000 INR/ Unit

Centrifugal Blowers For Hot Air Generators Specification

- Flow Rate

- 500 - 40,000 m3/hr

- Output Power

- As per blower rating

- Motor Power

- 1 HP to 50 HP

- Pressure Range

- Up to 500 mm WG

- Power

- 1.5 kW to 40 kW

- Max Pressure

- Up to 500 mm WG

- Life Span

- 8-10 Years

- Product Type

- Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 500 CFM to 40,000 CFM

- Pressure

- 70-250 mm WG

- Application

- Hot Air Generators, Industrial Heating

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2880 RPM

- Noise Level

- Below 80 dB

- Power Source

- Electric

- Voltage

- 220-415 V

- Weight

- 45 kg (Approx)

- Dimension (L*W*H)

- As per Model (Customizable)

- Color

- Blue & Silver

- Fan Housing Coating

- Powder Coated / Painted

- Mounting Type

- Base Mounted

- Drive Type

- Direct / Belt Driven

- Service

- On-site installation & after-sales support

- Operating Temperature

- Up to 250°C

- Insulation

- Optional for high temperature

- Inlet Size

- 150 mm to 1,200 mm

- Bearings

- Heavy duty, greased for life

- Phase

- Single / Three Phase

- Impeller Type

- Backward/Forward Curved

- Vibration Level

- Within IS Standard

Centrifugal Blowers For Hot Air Generators Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Week

- Delivery Time

- 7-30 Days

About Centrifugal Blowers For Hot Air Generators

Versatile Impeller and Drive Solutions

Select from backward or forward curved impeller types, which cater to different performance requirements. Both direct and belt-driven options ensure flexibility for varying installation spaces and operational preferences. The robust base-mounted design is adaptable to numerous settings, providing stable operation during industrial use.

Customized for Industrial Demands

Our blowers support customizable sizes and dimensions, with inlet diameters ranging from 150 mm to 1,200 mm. Housing coatings-powder-coated or painted-safeguard against corrosion in demanding environments. Additionally, insulation is available for high-temperature operations, further extending service life and performance reliability.

Comprehensive On-site Service and Support

We provide end-to-end installation and after-sales support, ensuring smooth integration into your process. Our on-site service team is available across India for maintenance and technical assistance, helping guarantee extended blower lifespan and consistent efficiency.

FAQ's of Centrifugal Blowers For Hot Air Generators:

Q: How is the centrifugal blower installed and maintained on-site?

A: Installation is carried out by our expert team, who ensure proper mounting, electrical connections, and safe commissioning. Maintenance includes routine inspections, lubrication of bearings (which are greased for life), and monitoring vibration levels, all within IS standards, to secure long-term reliability.Q: What are the benefits of using backward or forward curved impeller types?

A: Backward curved impellers offer higher efficiency and lower energy consumption, while forward curved impellers provide greater airflow at lower pressures. Selecting the appropriate type depends on your process requirements and desired operational outcomes.Q: When should optional insulation be considered for the blower?

A: Insulation becomes crucial when operating at high temperatures (up to 250C) to preserve motor life, prevent heat loss, and ensure safety. It is especially beneficial for hot air generator applications in industrial heating processes.Q: Where can these blowers be used, and what industries benefit most?

A: These centrifugal blowers are ideal for hot air generators and industrial heating systems, finding use in sectors such as manufacturing, textile, food processing, and thermal applications that require controlled air movement and pressure.Q: What is the process for customizing blower dimensions and specifications?

A: Clients can specify their requirements, such as inlet size, motor power, pressure range, and dimensions. Our engineering team then designs the blower model to fit the application, optimizing performance and installation compatibility.Q: What usage guidelines ensure optimal blower performance and life span?

A: Operate within the specified temperature, pressure, and capacity limits, keep noise below 80 dB, and utilize the recommended power source (220-415 V, 50 Hz). Regular service and adherence to manufacturer instructions will maximize service life (8-10 years).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Blowers Category

Custom Built Centrifugal Air Blowers

Price 28000-700000 INR / Unit

Minimum Order Quantity : 1 Unit

Output Power : As per Selection

Material : other , Mild Steel / Stainless Steel / Aluminum

Motor Speed : 1440/2880 RPM

Noise Level : Within IS Standards

Fume Extraction Blowers

Price 28000-700000 INR / Unit

Minimum Order Quantity : 1 Unit

Output Power : 2.2 kW

Material : other , Mild Steel

Motor Speed : 1440 RPM

Noise Level : Below 70 dB

Textile Blowers

Price 28000-700000 INR / Unit

Minimum Order Quantity : 1 Unit

Output Power : 7.5 kW

Material : other , Mild Steel / Cast Iron

Motor Speed : 2800 rpm

Noise Level : Below 85 dB

Centrifugal Forced Draft Boiler Fans

Price 28000-700000 INR / Unit

Minimum Order Quantity : 1 Unit

Output Power : 5.5 kW

Material : other , Mild Steel

Motor Speed : 1440 RPM

Noise Level : Below 80 dB

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free