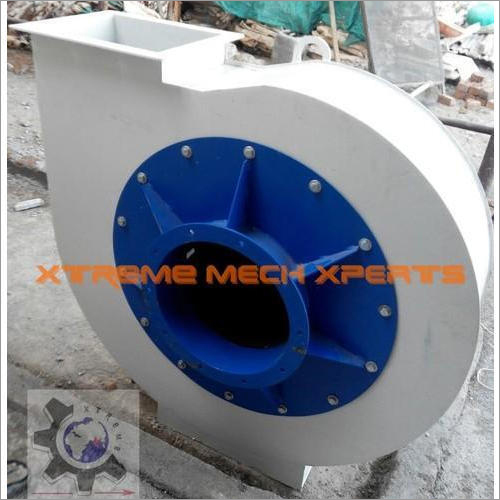

Centrifugal Forced Draft Boiler Fan

Price 28000-700000 INR/ Unit

Centrifugal Forced Draft Boiler Fan Specification

- Max Pressure

- 1800 Pa

- Flow Rate

- 5000 35000 m/hr

- Life Span

- 10+ years under normal usage

- Motor Power

- 7.5 kW

- Power

- 7.5 kW

- Pressure Range

- 600-1800 Pa

- Output Power

- 7.5 kW

- Product Type

- Centrifugal Forced Draft Boiler Fan

- Material

- Mild Steel

- Capacity

- 5000 35000 m/hr

- Pressure

- 600-1800 Pa

- Application

- Boiler Forced Draft, Industrial ventilation, exhaust systems

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2900 RPM

- Noise Level

- <80 dB(A)

- Power Source

- Electric

- Voltage

- 415 V

- Weight

- 320 kg

- Dimension (L*W*H)

- 1200 mm x 900 mm x 750 mm

- Color

- Industrial Grey

- Phase

- Three phase

- Finish

- Powder coated anti-corrosive finish

- Operating Temperature

- Up to 80C

- Drive Type

- Direct/ Belt Drive available

- Bearing Type

- Sealed ball bearings

- Static Pressure

- Upto 1800 Pa

- Blade Material

- Heavy gauge steel

- Efficiency

- High volume efficiency

- Mounting

- Base mounted

- Impeller Type

- Backward curved

- Airflow Direction

- Horizontal

- Inlet Size

- 450 mm 1200 mm

Centrifugal Forced Draft Boiler Fan Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Week

- Delivery Time

- 7-30 Days

About Centrifugal Forced Draft Boiler Fan

Engineered for Industrial Reliability

Manufactured in India for demanding environments, the fan is expertly designed to deliver consistent, high-efficiency airflow for boiler systems. Heavy gauge steel blades and an industrial-grade powder coating enhance durability and resistance to corrosion, making it an ideal choice for continuous operation in boilers, ventilation, and exhaust systems.

Versatile Installation and Operation

Offering both direct and belt drive options, the fan fits diverse installation requirements. Its base-mounted design, wide inlet size range, and sealed ball bearings allow stable, low-maintenance operation. Suitable for horizontal airflow, the fan combines robust construction with an optimized three-phase electric motor for superior performance at up to 80C operating temperature.

FAQ's of Centrifugal Forced Draft Boiler Fan:

Q: How is the Centrifugal Forced Draft Boiler Fan installed for optimal performance?

A: The fan is base-mounted, allowing secure installation on a stable surface near boiler or ventilation systems. Both direct and belt drive configurations are available to accommodate specific operational requirements and site constraints, ensuring optimal airflow and system efficiency.Q: What are the primary applications for this centrifugal fan?

A: This fan is primarily used for boiler forced draft, industrial ventilation, and exhaust systems, providing high-volume, reliable airflow for various heavy-duty processes in manufacturing, energy, and other industrial sectors.Q: When should maintenance be performed on the boiler fan?

A: Routine inspection and maintenance, such as checking sealed ball bearings and cleaning blades, are recommended periodically, typically every six months. The powder-coated finish and sealed bearings reduce maintenance frequency and protect against corrosion and dust accumulation.Q: Where is it manufactured and supplied?

A: The Centrifugal Forced Draft Boiler Fan is manufactured, supplied, and serviced in India, covering a wide range of industrial clients and boiler systems across the region.Q: What benefits does the backward curved impeller design provide?

A: The backward curved impeller design enhances energy efficiency, reduces noise, and helps maintain higher static pressure, ensuring the fan delivers stable, high-volume airflow with less wear, ideal for extended industrial use.Q: How is noise minimised during fan operation?

A: The fan's design, including robust insulated housing and precision-engineered heavy gauge steel blades, keeps operational noise levels below 80 dB(A). The sealed ball bearing system further dampens vibration and sound, contributing to a quieter work environment.Q: What is the process for selecting the correct fan capacity and pressure?

A: Selection involves evaluating the desired airflow rate (5000 - 35,000 m3/hr) and required static pressure (600 - 1800 Pa) based on system specifications. Consulting with the supplier ensures optimal matching to boiler or ventilation needs for efficiency and operational longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Blowers Category

Custom Built Centrifugal Air Blowers

Price 28000-700000 INR / Unit

Minimum Order Quantity : 1 Unit

Motor Power : 0.5 HP to 500 HP

Power : Up to 500 HP

Application : Other, Ventilation, Dust Extraction, Industrial Process, HVAC

Frequency (MHz) : 50 Hz

Centrifugal Suction Air Blowers

Price 28000-700000 INR / Unit

Minimum Order Quantity : 1 Unit

Motor Power : 0.75 kW to 11 kW

Power : 1 HP to 15 HP

Application : Other, Industrial ventilation, dust collection, air exhaust, fume extraction, HVAC systems

Frequency (MHz) : 50 Hz / 60 Hz

Centrifugal Forced Draft Boiler Fans

Price 28000-700000 INR / Unit

Minimum Order Quantity : 1 Unit

Motor Power : 7.5 HP

Power : 5.5 kW

Application : Other, Boiler Forced Draft

Frequency (MHz) : 50 Hz

Centrifugal Blowers For Hot Air Generators

Price 28000-700000 INR / Unit

Minimum Order Quantity : 1 Unit

Motor Power : 1 HP to 50 HP

Power : 1.5 kW to 40 kW

Application : Other, Hot Air Generators, Industrial Heating

Frequency (MHz) : 50 Hz

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free