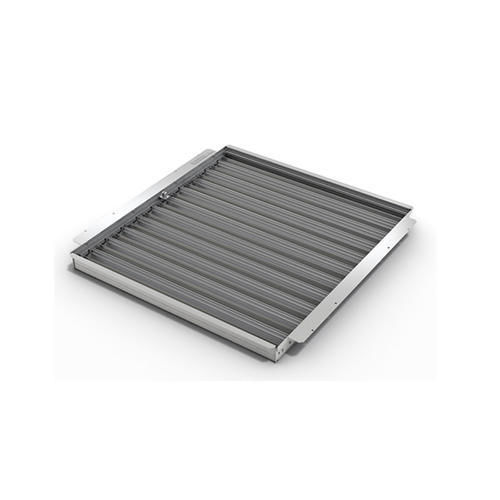

Guillotine Dampers

Price 32000 INR/ Piece

Guillotine Dampers Specification

- Features

- Robust construction, Low leakage, Customizable sizes, High temperature resistance

- Operating Pressure

- Up to 500 mmWC

- Automation Grade

- Manual, Motorized, or Pneumatic options

- Power Source

- Electric / Pneumatic / Manual

- Accessories Type

- Sealing air systems, Limit switches, Position indicators

- Accuracy

- High sealing efficiency up to 99%

- Control System

- Local / Remote Electric, Pneumatic or Manual control

- Surface Treatment

- Powder coated / Painted / Galvanized

- Machine Type

- Industrial air and gas flow management equipment

- Technology

- Fabricated, damper blade slides through frame using mechanical actuator

- Type

- Sliding Blade Damper (Guillotine Type)

- Material

- Mild Steel / Stainless Steel

- Function

- Isolation and shut-off of gas or air duct lines

- Application

- Power plants, Cement industries, Chemical and Petrochemical industries, HVAC systems, Dust extraction systems

- Voltage

- 230V/415V AC for motorized operation

- Temperature Range

- Ambient up to 900°C (subject to material)

- Mounting

- Flanged or welded

- Blade Material

- Single or multi-layered steel for high temperature and pressure service

- Size Range

- 300 mm to 3000 mm (custom sizes available)

- Leakage Class

- Class II to Class IV (as per IS/ASME)

- Blade Movement

- Linear sliding with rack & pinion or screw actuator

- Frame Construction

- Rigid fabricated steel with reinforced stiffeners

- Seal Type

- Metal to metal or resilient seals for minimal leakage

About Guillotine Dampers

Versatile Applications for Guillotine Dampers

Guillotine Dampers are eminently suitable for use in power plants, cement industries, chemical and petrochemical operations, HVAC setups, and dust extraction systems. Designed for potent isolation and shut-off, these dampers reliably manage gas and air duct lines under high pressure and temperature scenarios. Their usage type ranges from manual to fully automated control, supporting both new installations and retrofitting existing systems to guarantee optimal air flow and process safety across critical industrial sectors.

Domestic Market and Global Certifications

Guillotine Dampers command a robust market value within India's industrial sector and are backed by compliance to IS and ASME standards. Domestically, they find strong market demand via purchase orders from cement factories, refineries, and HVAC contractors. Main export markets include Southeast Asia and the Middle East, with major consignments supported by certified quality assurance. An accurate estimate of export growth hinges on customized solutions and certified performance, adding value to both domestic and overseas clients.

FAQ's of Guillotine Dampers:

Q: How do Guillotine Dampers provide effective isolation in air and gas flow management?

A: Guillotine Dampers utilize a sliding blade design with high sealing efficiency (up to 99%) and reinforced steel frames to ensure potent isolation and minimal leakage in air and gas ducts.Q: What types of actuators are available for Guillotine Dampers?

A: Actuators include rack & pinion, screw drive, with options for manual, motorized (electric), or pneumatic operation, providing versatile control options tailored to application demands.Q: When should industries consider installing Guillotine Dampers?

A: Industries should install Guillotine Dampers when high temperature, pressure, and strict isolation needs arise in processes such as power generation, cement manufacturing, or chemical handling.Q: Where are Guillotine Dampers commonly used?

A: Guillotine Dampers are commonly used in applications across power plants, cement industries, chemical or petrochemical units, HVAC systems, and dust extraction setups.Q: What is the typical process for purchasing a Guillotine Damper?

A: Purchasing involves submitting a purchase order based on required size, material, leakage class, and control system requirements, followed by customization and manufacturing as per project specifications.Q: How can users benefit from the certified and customizable design of these dampers?

A: Users benefit from higher market value and reliable performance, as each damper is certified to IS/ASME standards and customizable for specific pressure, temperature, and operational requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Dampers Category

Hot Air Dampers

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Durable Rustresistant

Operating Pressure : Variable

Automation Grade : Automatic

Material : Stainless Steel

Butterfly Dampers

Price 2500 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Corrosionresistant durable high sealing capability

Operating Pressure : Medium pressure range

Automation Grade : Manual or Automatic

Material : Mild Steel

Motorized Multi Louver Dampers

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Multilouver design Durable construction Motorized operation

Operating Pressure : Up to 3000 Pa

Automation Grade : Automatic

Material : Aluminum or Stainless Steel

Industrial Pneumatic Dampers

Price 9000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Durable construction efficient performance easy installation

Operating Pressure : Up to 10 bar

Automation Grade : SemiAutomatic

Material : Aluminum or Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free